Rita chapot

Display Design Portfolio

Examples of Work

Click to Enlarge Photos

Case Study 1:

Shoppers Drug Mart, Canada, 1000 doors

Adapted client-selected design for brand introduction to mass Canadian market.

Program initially intended to last 6 months.

Overhauled display function while maintaining original style. New “hybrid” design has semi-permanent styrene base with temporary vac-form insert panels.

Reduced per unit cost by 23%.

Reduced waste by utilizing full life-cycle of materials.

New hybrid design reduced update costs by 76%.

Due to program success, theBalm has been offered a permanent position in 1000 doors.

Case Study 2:

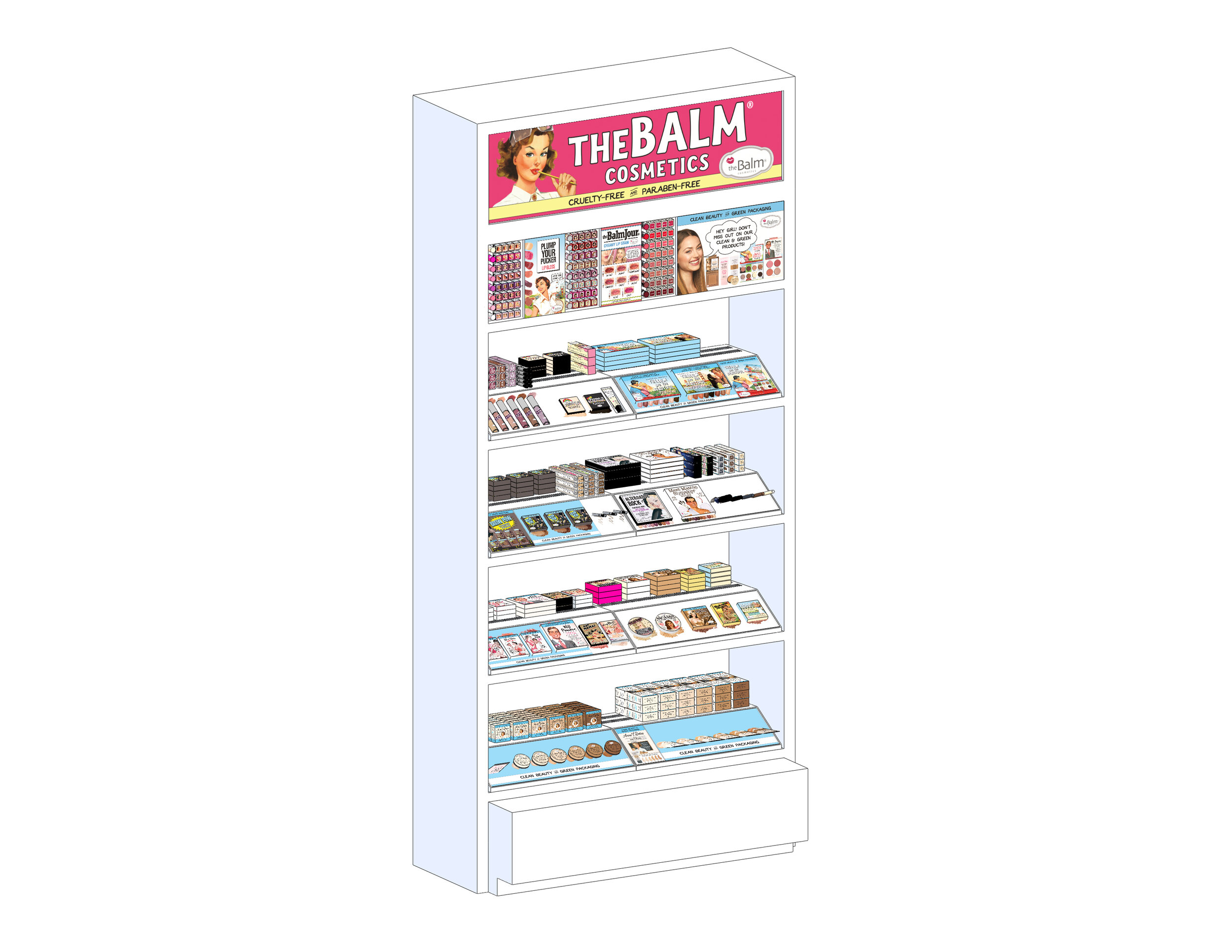

2024 flagship Free Standing Unit

Original concept renderings for a new flagship mass-market free standing unit. The unit is sized for easy placement in pharmacy floor plans, displays a “hero product” range on one unit, and holds a full product range on 2 units.

Intended as a readily available generic brand option, a steel frame was selected to withstand high traffic usage without maintenance. Robust enough to provide years of in-store use, it also allows the unit to be resold and relocated multiple times without damage. Unit ships in a single box and fits on a standard palette.

Movable shelves and insert artwork accommodate an ever changing product assortment and international placement. The unit comes with clear acrylic insert options to support the most popular products, such as caddies for displaying an extensive lipstick shade range in a compact space.

For an indie brand that typically creates all custom bespoke fixtures, this unit utilizes markets of scale. Increasing production runs to cover both pre-sold and warehouse-stock units keeps prices low and availability high.

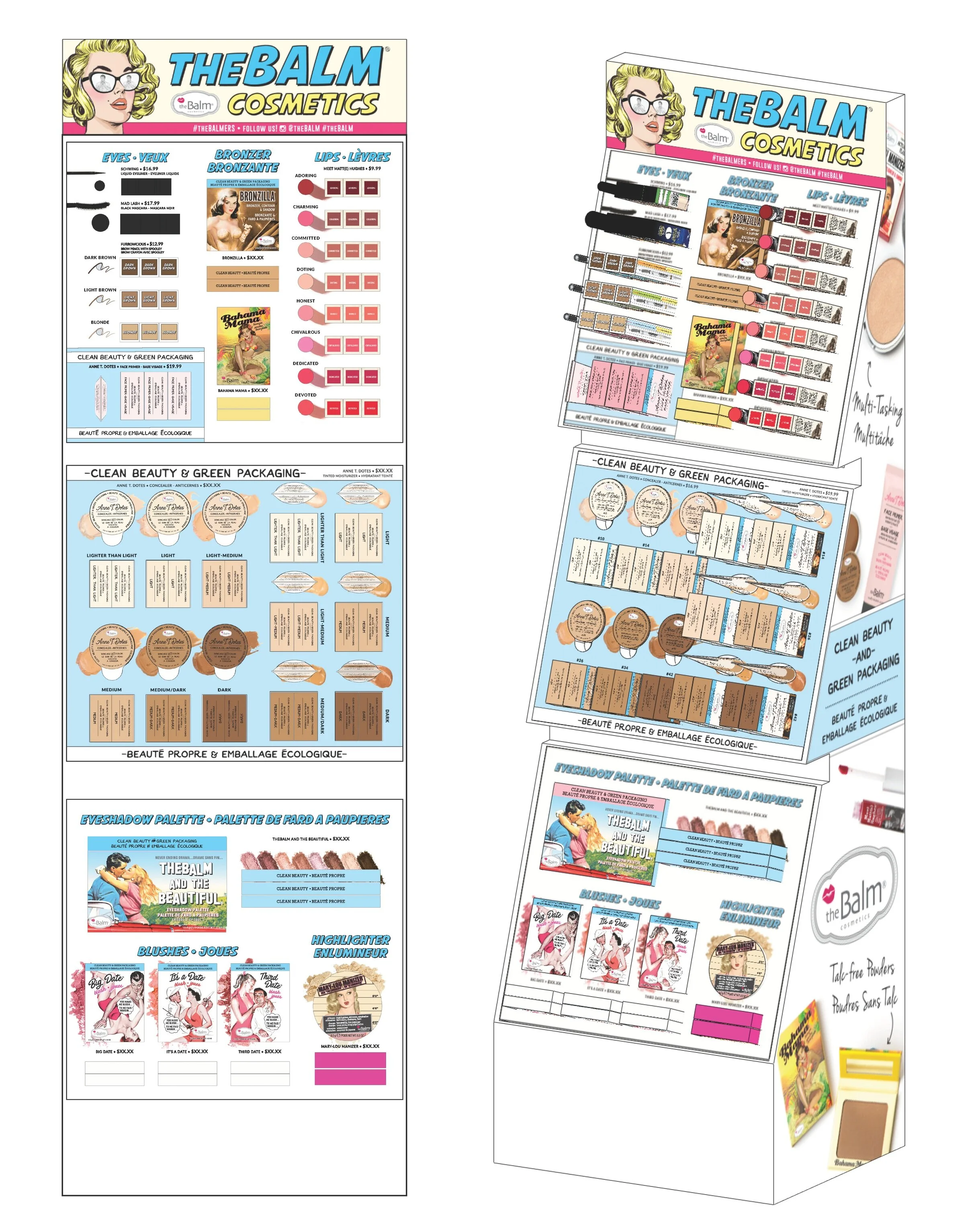

Case Study 3:

Di Beauty & Care: France, Germany, Belgium, & Luxembourg, 400 doors

theBalm products placed in generic store display.

No branding or guidance for customer.

Limited range of products.

Too much stock of poorly selling skus.

Proposal doubles product assortment & increases graphic space by 20%.

Semi-flexible product panels are inserted into existing base unit, significantly reducing expected costs.

Clearly designated tester & stock areas keep unit clean & easy to shop.

Based on proposal, the client agreed to double product assortment in stores & increased display size.

Display requires no special equipment to update, allowing stores to easily introduce new products. Eliminates need for “merchandising agency” labor.

Addition of LED lighting & increased “waterfall” effect enhances visibility of lower products.

Designer & Project Manager:

My work flow

After an initial conversation with the client, I design their display using CAD software. I prepare & distribute technical packets to a network of manufacturers for bids.

As project manager, I present budgets, timelines, and mockups both internally & direct to client, oversee the development of graphic art, determine the product assortment & stock quantity, & select a manufacturer.

After selecting a design concept, I validate all manufacturing drawings, coordinate dieline development, issue purchase orders, review prototypes, & optimize the design.

I troubleshoot any production issues & coordinate between the client, manufacturer, & shipping departments. I elicit feedback from stores, develop solutions as needed, & coordinate updates.

I frequently make contributions to non-displays departments.

For example, while working on the Shopper’s Drug Mart project, I instituted a brand-wide overhaul of packaging to eliminate artwork orientation issues. Originally (left) warning labels were visible when products were inserted into caddies. Now (right) the artwork & shade name are always visible, regardless of orientation.